While prevention costs focus on preventing defects and errors from occurring in the first place, appraisal costs focus on detecting and correcting defects after they occur. Prevention costs play a critical role in ensuring product or service quality and enhancing overall business performance. By investing in proactive measures to prevent defects, errors, or failures, companies can reduce costs, improve quality, mitigate risks, and gain a competitive advantage in the marketplace.

Key Aspects of Prevention Costs

The worst type of cost out of these four categories of the cost of poor quality is the external failure costs. Organizations should make their best effort to reduce the external failure cost. PCA should be used whenever a business is making decisions that could impact the quality of their products or services.

COPQ Contributing Towards Improved Efficiency

Here are the best practices for implementing prevention costs in an organization. Here are some common challenges companies face when implementing prevention costs. The quality of the supplies used during the production process can significantly impact the final output of goods or services. Investing in high-quality supplies can prevent issues such as defective products or services.

What is the difference between prevention costs and appraisal costs?

Prevention costs refer to the expenses incurred by a business to prevent defects, errors, or problems in its products or processes. These costs are part of a proactive quality management approach aimed at identifying and eliminating potential issues before they occur. Understanding prevention costs is crucial for learners in business and management to grasp the importance of quality assurance and its impact on overall business performance. In conclusion, prevention costs are an essential aspect of business management, crucial in ensuring customer satisfaction, improving product and service quality, and maintaining a competitive edge.

- By investing in quality control measures, businesses can differentiate themselves from their competitors and establish a reputation for quality.

- When a company produces high-quality products and services, it can contribute to the well-being and safety of the community.

- This can lead to products and services that are more efficient, easier to use, and more reliable.

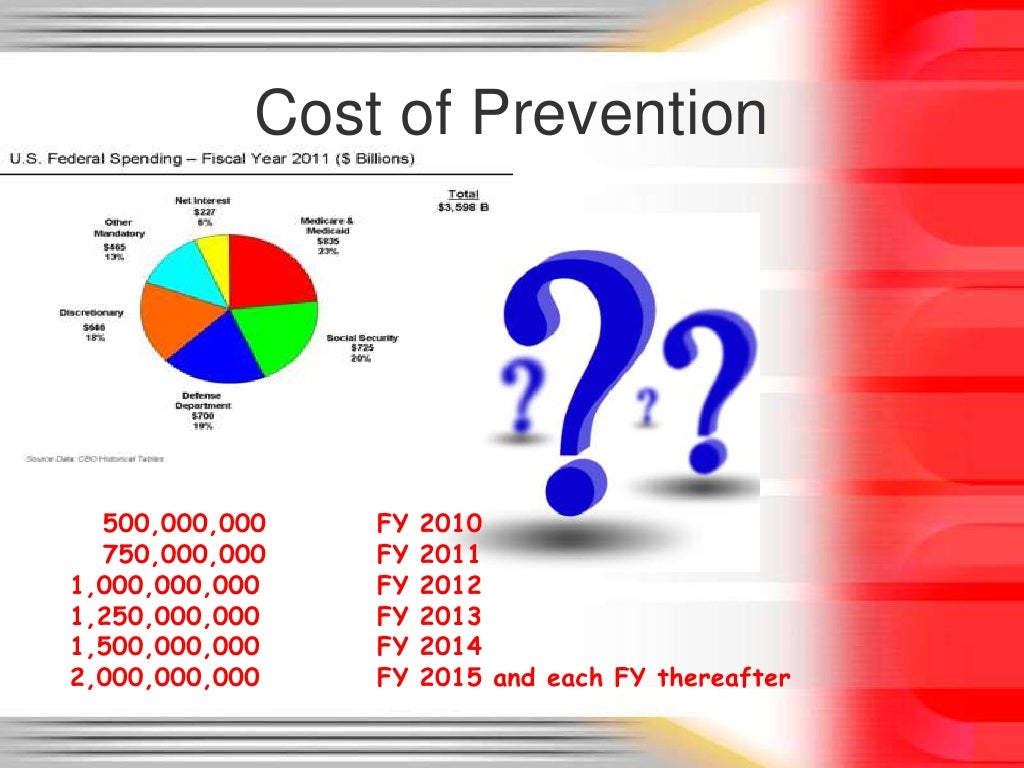

The cost that’s like no other: Why effective prevention is an investment

Yes, investing in prevention can reduce appraisal costs by minimizing the number of defects that need to be detect and correct. Look out for the ratio between what you’re spending on prevention (investments and costs) and your costs of internal and external failure. In this chapter, you’ve explored the difference between prevention costs and prevention investments—and begun considering where investments in prevention might eliminate or reduce those costs. (Think of all those tedious prevention-related tasks that can, and should, be automated.) We can all agree that these prevention costs are bad.

For example, tracking repair and warranty expenses by product line or business unit spotlights which areas incur the greatest quality costs. Companies can use this information to focus quality improvement projects on problem processes first. Tracking quality costs allows businesses to identify problem areas, benchmark performance over time, and prioritize quality improvement initiatives.

Understanding the cost of poor quality is critical for organizations looking to improve profitability, efficiency, and customer satisfaction. Appraisal costs are expenses relate to evaluating and measuring the income tax definition quality of products or services to identify defects after production or service delivery. The important thing is that it is considered when any decision is being made about quality and customer satisfaction.

By taking steps to anticipate problems and create solutions, businesses can avoid issues that reduce efficiency and profitability. Prevention costs can have both positive and negative effects on employee productivity. On the one hand, investing in prevention measures can help employees avoid the frustration and inefficiency of correcting mistakes after they’ve been made. Smaller companies may struggle to allocate the necessary resources to implement prevention costs, as they may have limited personnel or time to spare. High-quality products that meet requirements consistently lead to improved customer satisfaction. With fewer complaints and returns to process, customers have a better brand experience.

In a business setup, the whole organization is responsible for ensuring quality production. While the top-level management frames the quality standards, the operational-level staff takes charge of following these standards, policies, and protocols. The quality control department is primarily responsible and accountable for implementing the prevention cost, along with other cost of quality (COQ) measures. Furthermore, the engineering department ensures that the product design aligns with the desired quality requirements of usage convenience, reliability, sturdiness, and efficiency. Prevention costs play a crucial role in ensuring product or service quality, customer satisfaction, and overall business success. By investing in proactive measures to prevent defects or errors, companies can minimize quality issues, reduce costs, and maintain a competitive edge in the market.

Appraisal costs help verify quality requirements before products reach customers. However, analyzing appraisal costs can identify opportunities to streamline quality control activities. Tracking prevention costs helps identify areas for future investment to prevent nonconformities.